Description

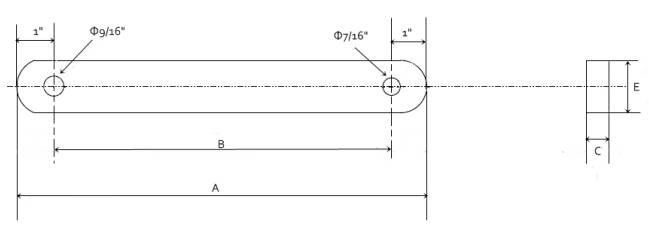

Technical Parameters and Drawings

| HE Code | Dimensions | Wt./100 | |||

| A | B | C | E | kgs | |

| HEFB-0626 | 26” (660.4) | 24” (609.6) | 1/4” (6.35) | 1 1/4″(31.75) | 104.33 |

| HEFB-0628 | 28” (711.2) | 26” (660.4) | 1/4” (6.35) | 1 1/4″(31.75) | 108.86 |

| HEFB-0630 | 30” (762.0) | 28” (711.2) | 1/4” (6.35) | 1 1/4″(31.75) | 115.67 |

| HEFB-0632 | 32” (812.8) | 30” (762.0) | 1/4” (6.35) | 1 1/4″(31.75) | 124.74 |

| HEFB-0634 | 34” (863.6) | 32” (812.8) | 1/4” (6.35) | 1 1/4″(31.75) | 133.81 |

| HEFB-0636 | 36” (914.4) | 34” (863.6) | 1/4” (6.35) | 1 1/4″(31.75) | 142.88 |

| HEFB-0638 | 38″(965.2) | 36” (914.4) | 1/4” (6.35) | 1 1/4″(31.75) | 151.95 |

| HEFB-0520 | 20″(508) | 18″(457.2) | 7/32″(5.56) | 1 7/32″(30.95) | 63.5 |

| HEFB-0526 | 26” (660.4) | 24” (609.6) | 7/32″(5.56) | 1 7/32″(30.95) | 83.91 |

| HEFB-0528 | 28” (711.2) | 26” (660.4) | 7/32″(5.56) | 1 7/32″(30.95) | 90.72 |

| HEFB-0530 | 30” (762.0) | 28” (711.2) | 7/32″(5.56) | 1 7/32″(30.95) | 97.52 |

| HEFB-0532 | 32” (812.8) | 30” (762.0) | 7/32″(5.56) | 1 7/32″(30.95) | 102.06 |

| 1. Tolerance: ±5% | |||||||||

| 2. All dimensions are in inch.

3. Material: carbon steel |

|||||||||

| 4. Finish: hot dip galvanized | |||||||||

| 5. Customized sizes are available at request. | |||||||||

| Product Description: | |||||||||

|

|||||||||

| Product Details: | |||||||||

| Name: flat crossarms, cross arm braces, flat braces, extension arms | |||||||||

| HS code: 7326 | |||||||||

| Model: ANSI/ASME | |||||||||

| Package: bulk packing; palletized; as required | |||||||||

| Trademark: HE, as required | |||||||||

| Origin: China | |||||||||

| Raw material: carbon steel Q235 | |||||||||

| Finish: HDG | |||||||||

| ODM&OEM service: yes | |||||||||

| Sample: available, FOC | |||||||||

| Payment term: T/T, 30% prepayment and 70% balance against B/L | |||||||||

| Certificate: ISO | |||||||||

| Delivery time: 20-40 days | |||||||||

| MOQ: 500kgs | |||||||||

| Export term: FOB; CIF | |||||||||

| Production capacity pcs/day: 2000 | |||||||||

| Minimum tensile strength lbs.: 7000 | |||||||||

| Overall length in: 20, 26, 28, 30,etc. | |||||||||

| Mounting hole center in: 18, 24, 26,etc. | |||||||||

| Weight/100 kg: 104.33,etc. | |||||||||

| Hole dia. in: 7/16, 9/16 | |||||||||

| Steel size in: 7/32 X 1-7/32, 1/4×1 1/4 | |||||||||