Description

Technical Parameters and Drawings

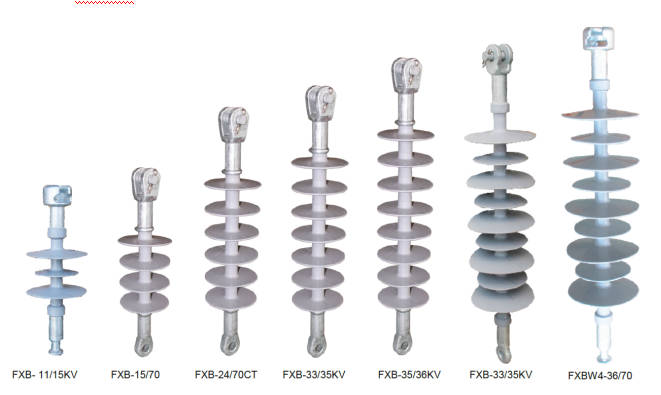

Tension indulatos

| HE CODE | Rated voltage (kV) |

Rated failing Load (KN) |

Section length (mm) ±15 |

Dry arcing distance (mm) |

Min. Creepage distance (mm) |

Fin diameter (mm) |

Lightning Impulse Withstand voltage (kV) |

Power frequency 1min wet Withstand voltage |

| FXB-11/70CT | 11 | 70 | 350 | 160 | 500 | 125/90 | 75 | 50 |

| FXB1-15/70CT | 15 | 70 | 350 | 185 | 420 | 100 | 95 | 55 |

| FXB1-24/70CT | 24 | 70 | 455 | 275 | 650 | 100 | 155 | 70 |

| FXB1-24/70ST | 24 | 70 | 455 | 275 | 720 | 100 | 155 | 70 |

| FXB1-33/70CT | 33 | 70 | 500 | 320 | 840 | 100 | 75 | 200 |

| FXB-36/70CT | 36 | 70 | 640 | 365 | 860 | 100 | 80 | 210 |

| FXBW4-36/70SB | 36 | 70 | 670 | 455 | 1350 | 140/110 | 95 | 230 |

| FXBW4-36/70CT | 35 | 70 | 670 | 455 | 1350 | 140/110 | 95 | 230 |

| FXB- 66/70SB | 66 | 70 | 890 | 704 | 2240 | 140/110 | 185 | 410 |

| FXB3-110/100(120)SB | 110 | 100 (120) | 1260 | 1050 | 3150 | 142/110 | 335 | 750 |

| FXB3-132/100(120)SB | 132 | 100 (120) | 1395 | 1150 | 3450 | 142/110 | 350 | 820 |

Line Post insulators

| HE CODE | Rated voltage (kV) |

Min. Creepage distance (mm) |

Rated failing Load (KN) |

Lightning Impulse Withstand voltage (kV) |

Power frequency 1min wet Withstand voltage |

Section length (mm) ±5 |

Dry arcing distance (mm) |

|

| Bending | Twist | |||||||

| FZ-11/15 | 11 | 560 | 6 | 1.2 | 45 | 110 | 470 | 230 |

| FZ-24/33 | 24 | 1250 | 8 | 1.5 | 95 | 180 | 585 | 310 |

| FZ-33/36 | 33 | 1250 | 8 | 1.5 | 95 | 180 | 740 | 475 |

| FZ-66/69 | 66 | 2160 | 12.5 | 2 | 170 | 350 | 865 | 740 |

Post Insulators

| HE CODE | Rated voltage (kV) |

Rated Bending Load (KN) |

Section length (mm) ±15 |

Dry arcing distance (mm) |

Min. Creepage distance (mm) |

Sheds Distance (mm) |

Lightning Impulse Withstand voltage (kV) |

Power frequency 1min wet Withstand voltage |

| FZSW-11-4 | 11 | 4 | 215 | 130 | 290 | 105/78 | 75 | 42 |

| FZSW 15-5 | 15 | 5 | 260 | 185 | 600 | 138/112 | 105 | 55 |

| FZSW-24-8 | 24 | 8 | 355 | 255 | 750 | 138/112 | 145 | 65 |

| FZSW 33-8 | 33 | 8 | 420 | 340 | 1200 | 126/92 | 150 | 70 |

| FZSW 36-10 | 36 | 10 | 500 | 390 | 1200 | 138/112 | 175 | 75 |

| FZSW 69-12.5 | 69 | 12.5 | 760 | 640 | 2010 | 146/117 | 410 | 185 |

| FZSW 32-12.5 | 132 | 12.5 | 1200 | 1900 | 3200 | 190/152 | 650 | 230 |

Pin insulators

| HE CODE | Rated voltage (kV) |

Rated Bending Load (KN) |

Section length (mm) ±15 |

Dry arcing distance (mm) |

Min. Creepage distance (mm) |

Sheds Distance (mm) |

Lightning Impulse Withstand voltage (kV) |

Power frequency 1min wet Withstand voltage |

| FPQ-11-5 | 11 | 5 | 270 | 140 | 350 | 138/110 | 60 | 45 |

| FPQ-15-5 | 15 | 5 | 330 | 195 | 490 | 138/110 | 65 | 140 |

| FPQ-24-8 | 24 | 8 | 390 | 260 | 720 | 140/112 | 70 | 155 |

| FPQ-33-8 | 33 | 8 | 445 | 295 | 1050 | 140/112 | 75 | 150 |

| FPQ-36-10 | 36 | 10 | 500 | 330 | 1200 | 140/112 | 95 | 200 |

| HE CODE | Rated voltage (kV) |

Rated Bending Load (KN) |

Section length (mm) ±15 |

Dry arcing distance (mm) |

Min. Creepage distance (mm) |

Sheds Distance (mm) |

Lightning Impulse Withstand voltage (kV) |

Power frequency 1min wet Withstand voltage |

| FPQ-11-5 | 11 | 5 | 270 | 140 | 350 | 138/110 | 60 | 45 |

| FPQ-15-5 | 15 | 5 | 330 | 195 | 490 | 138/110 | 65 | 140 |

| FPQ-24-8 | 24 | 8 | 390 | 260 | 720 | 140/112 | 70 | 155 |

| FPQ-33-8 | 33 | 8 | 445 | 295 | 1050 | 140/112 | 75 | 150 |

| FPQ-36-10 | 36 | 10 | 500 | 330 | 1200 | 140/112 | 95 | 200 |

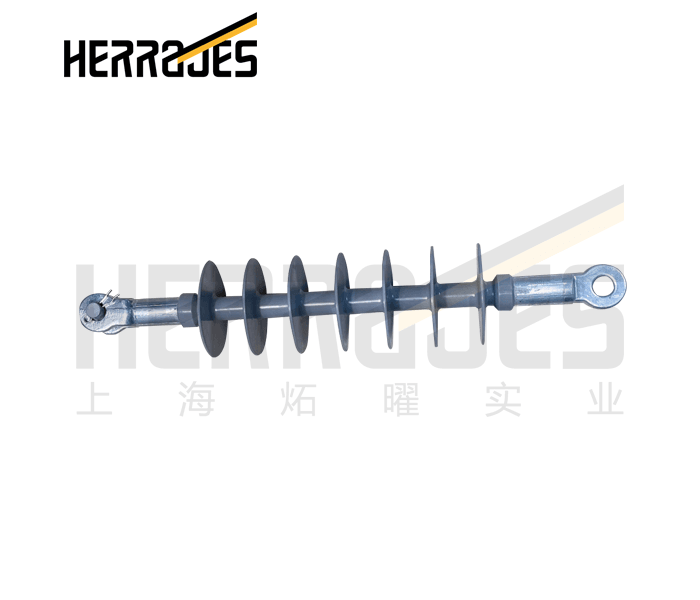

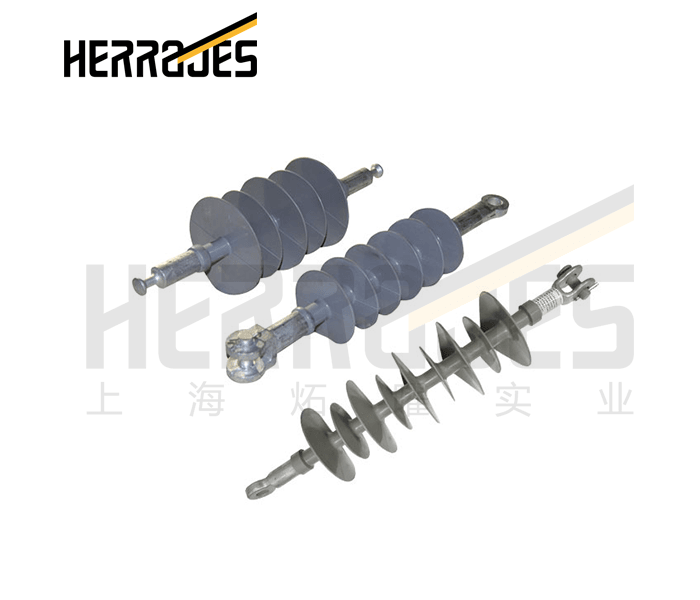

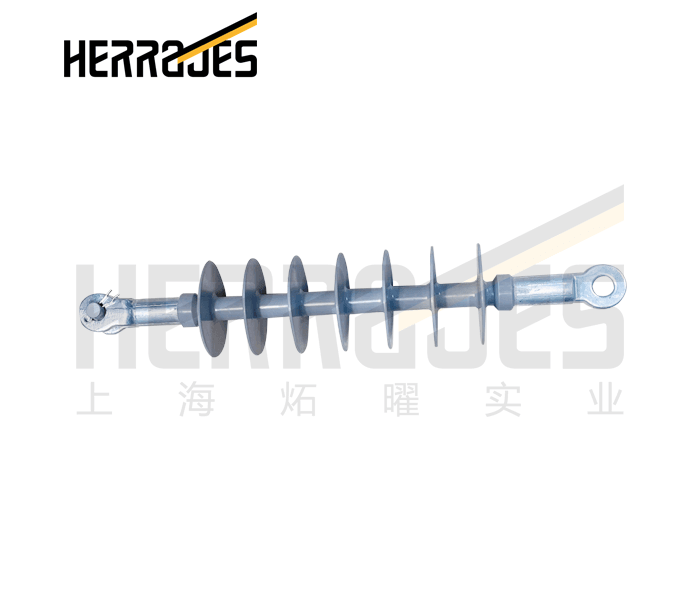

Product Description:

The composite insulator product consists of three parts: glass fiber epoxy resin rod, silicone rubber shed, and hardware. Its silicone rubber shed adopts the integral injection molding process, which solves the key problem affecting the reliability of composite insulators, and the electrical breakdown of the interface is solved. The connection between the glass lead rod and the metal fittings adopts the most advanced crimping tool and is equipped with an automatic sonic flaw detection system. It has high strength, beautiful appearance, small size and light weight. The metal fittings are galvanized to prevent rust and can be interchanged with porcelain insulators. Use, this product has a reliable structure, does not damage the mandrel, and can give full play to its mechanical strength.

Composite insulators mainly rely on unidirectional glass fiber reinforced resin pulling rods (commonly known as mandrels) to bear the mechanical load. The most prominent performance characteristics of FRP rods are high tensile strength and specific strength. The glass fibers in the pulling rod are arranged along the axial bearing direction, so that it has a high axial tensile strength, generally up to 1000 MPa or more. Therefore, the tensile failure strength of a pulling rod with a diameter of only 18 mm can reach more than 250 kN. And because the density of the pulling rod is generally only 2.0 g/cm3, its specific strength (ratio of tensile strength to weight) is 5 to 6 times that of high-quality carbon structural steel. The characteristics of high strength and high specific strength of the drawing rod are the basis for the high strength, light weight and small rod diameter of the composite insulator.

Although the composite insulator completely relies on the glass fiber pulling rod to bear the mechanical load, the strength of the mandrel is not equal to the strength of the composite insulator, because the mandrel must transmit the load through the end attachment of the insulator in order to communicate with the tower and the transmission line. wires are connected. The end connection must be the place where the mechanical stress is most concentrated, and different connection structures will also lead to different degrees of stress concentration. Therefore, the mechanical strength of the composite insulator actually depends more not on the mechanical strength of the core rod, but on its The mechanical strength of the end connection, that is, the utilization strength of the mandrel. The composite insulators with the same core rod and different connection structures have different mechanical strengths, so the utilization strength of the core rods is different.

Product Details:

Name: composit Insulators, rubber insulators.

HS code: 85469000

Package: carton packing; palletized; as required

Trademark: HE, as required

Origin: China

Raw material: composite material

Finish: Plain

ODM&OEM service: yes

Sample: available, FOC

Payment term: T/T, 30% prepayment and 70% balance against B/L

Certificate: ISO

Delivery time: 20-40 days

MOQ: 500pcs

Export term: FOB; CIF

Production capacity pcs/day: 2000