Description

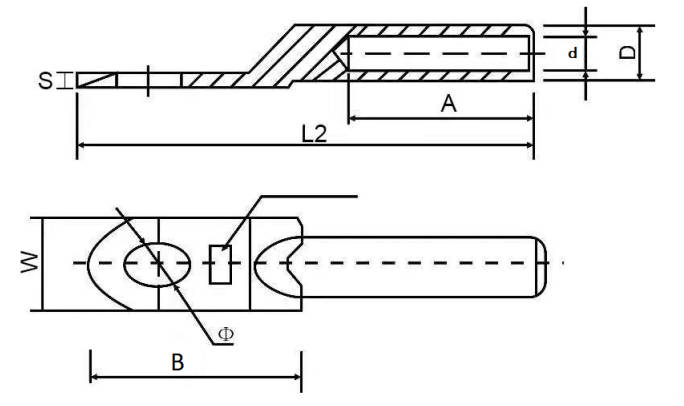

Technical Parameters and Drawings

| HE Code | L2 mm | B mm | A mm | W mm | S mm | D mm | d mm | φ mm | Weight(g) |

| HEDT-16 | 64 | 20 | 28 | 14.5 | 2 | 10 | 6.5 | 8.5 | 8.73 |

| HEDT-25 | 68 | 22 | 28 | 16 | 2.2 | 11 | 7.2 | 8.5 | 11.2 |

| HEDT-35 | 74 | 24 | 30 | 18 | 2.3 | 12 | 8.5 | 10.5 | 13.9 |

| HEDT-50 | 80 | 26 | 39 | 20 | 2.6 | 14 | 9.5 | 10.5 | 20 |

| HEDT-70 | 90 | 32 | 41.5 | 23 | 2.8 | 16 | 11.5 | 12.5 | 26 |

| HEDT-95 | 98 | 34 | 44 | 26 | 3.2 | 18 | 13.5 | 12.5 | 38.3 |

| HEDT-120 | 103 | 35 | 47 | 28 | 3.5 | 20 | 15.5 | 14.5 | 49.3 |

| HEDT-150 | 112 | 40 | 48 | 30 | 3.8 | 22 | 16.7 | 14.5 | 64 |

| HEDT-185 | 118 | 42 | 50 | 33 | 3.8 | 24 | 18.5 | 16.5 | 77.8 |

| HEDT-240 | 130 | 45 | 56 | 25 | 5 | 28 | 21 | 16.5 | 114 |

| HEDT-300 | 145 | 52 | 60 | 42 | 5.2 | 32 | 23 | 21 | 176 |

Notes:

| 1. Tolerance: ±5% | |

| 2. All dimensions are in MM except for marked. | |

| 3. Customized sizes are available at request.

|

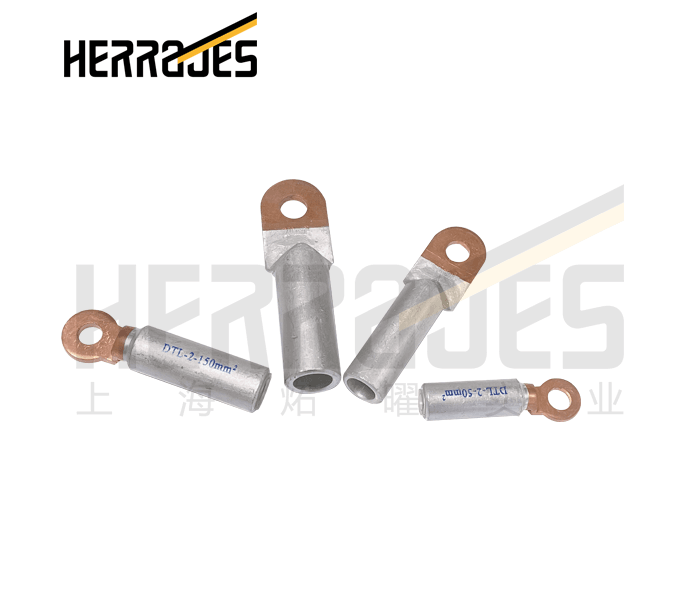

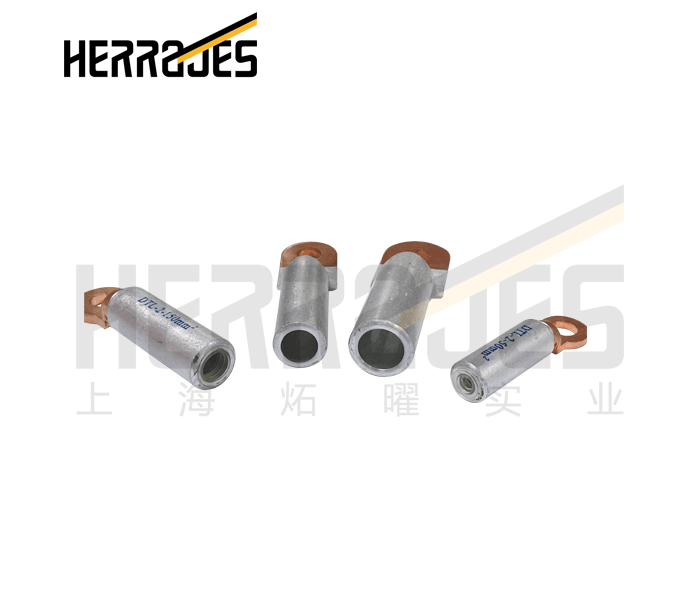

Product Description:

The HEDT series Bimetal terminals are made from T2 copper and alumiumm alloy, with reliable quality. They are mainly used for the connection between copper and alluminum conductor in power distribution system.

Why do we need to use Aluminum-copper terminals?

The connection between the copper wire and the aluminum wire will cause aluminum oxide for a long time, and the contact resistance at the connection will increase and generate heat, which will easily cause a building fire when the circuit is on and off. So use a special copper-aluminum transition clip. Avoid unnecessary troubles! Copper-aluminum wire connection device (commonly known as “copper-aluminum nose”)

If the copper wire and the aluminum wire are directly hinged together, the joint is easily oxidized, resulting in an increase in resistance, which makes it easier to burn out. The real reason for this damage is that the aluminum element is more active than the copper element, and there will be many micro-potentials (that is, micro-batteries) on the copper-aluminum junction surface, resulting in micro-electrocorrosion, and the contact resistance will increase over time. For ordinary homework, it is more reliable to tin the copper first and then connect.

In the power system, copper and aluminum are directly connected, and galvanic corrosion will occur when current flows. Therefore, copper-aluminum transition should be used, or a tin sheet should be placed in the middle of the contact surface, and a layer of conductive paste should be applied if possible. When connecting ordinary households, the copper wire can be tinned and then connected to the aluminum wire to avoid galvanic corrosion.

Product Details:

Name: Bimetal terminals, compression terminals, copper terminals.

HS code: 853890

Model:

Package: bulk packing; palletized; as required

Trademark: HE, as required

Origin: China

Raw material: aluminum and copper

Finish: tin plated

ODM&OEM service: yes

Sample: available, FOC

Payment term: T/T, 30% prepayment and 70% balance against B/L

Certificate: ISO

Delivery time: 20-40 days

MOQ: 500pcs

Export term: FOB; CIF

Production capacity pcs/day: 2000