Description

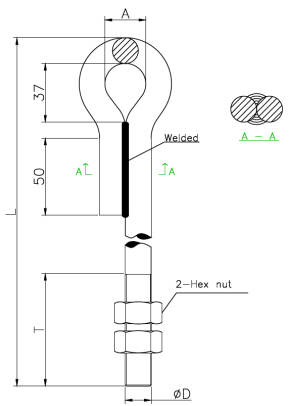

Technical Parameters and Drawings.

| HE Code | Dimensions | Min tensile strength | |

| L | D | KN | |

| HETR-1618 | 1800 | 5/8” (16) | 60 |

| HETR-1620 | 2000 | 5/8” (16) | 60 |

| HETR-1624 | 2400 | 5/8” (16) | 60 |

| HETR-1630 | 3000 | 5/8” (16) | 60 |

| HETR-1918 | 1800 | 3/4” (19) | 93 |

| HETR-1920 | 2000 | 3/4” (19) | 93 |

| HETR-1924 | 2400 | 3/4” (19) | 93 |

| HETR-1930 | 3000 | 3/4” (19) | 93 |

| 1. Tolerance: ±5% | |

| 2. All dimensions are in mm.

3. Material: carbon steel |

|

| 4. Finish: hot dip galvanized | |

| 5. Customized sizes are available at request.

|

|

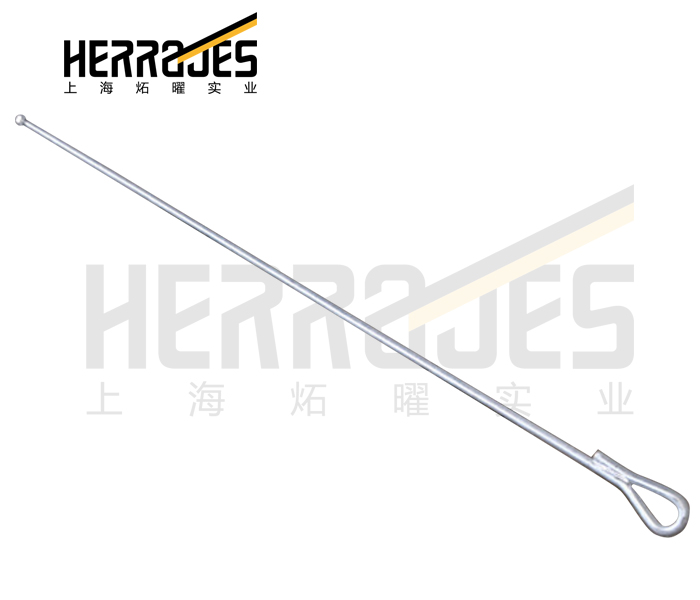

| Product Description:

Welded anchor rods are partial threads, assembled with two nuts. Normally they are installed with earthing plate in the earth Anchor rods are designed to anchor the guy wire to the ground. The above are typical only, please consult Shanghai Herrajes for further information.

|

|

| Product Details: | |

| Name: double end rods, pisa rods, threaded double end rods | |

| HS code: 7318159090 | |

| Model: ANSI/ASME | |

| Package: bulk packing; palletized; as required | |

| Trademark: HE, as required | |

| Origin: China | |

| Raw material: carbon steel Q235 | |

| Finish: HDG | |

| ODM&OEM service: yes | |

| Sample: available, FOC | |

| Payment term: T/T, 30% prepayment and 70% balance against B/L | |

| Certificate: ISO | |

| Delivery time: 20-40 days | |

| MOQ: 500kgs | |

| Export term: FOB; CIF | |

| Production capacity pcs/day: 2000 | |

| Minimum tensile strength lbs.: 7800 | |

| Diameter in: 5/8, 3/4, 7/8, 1,etc. | |

| Length in: 12, 14, 16, 20, 24, 26,etc.

Analysis of the Causes of Serious Corrosion of the Anchoring Rod During the renovation of the power line, the anchor rods above the ground were found with good condition, but 20-40cm below the ground were severely corroded, and the most serious corrosion brougth a possibility that the rod will break at any time. So the Anchor rod need to be inspected and replaced in about 5 to 7 years; if it is in the heavily polluted area, the service life will be shorter. The main reason for the corrosion of the grounding down-conductor and the pull rod is the serious environmental pollution, accounting for 65%, followed by the poor production process, insufficient galvanized layer or man-made damage, etc. |

|